When it comes to fabric printing, two popular methods stand out: Sublimation Printing and Direct-to-Garment (DTG) Printing. Each offers unique benefits and challenges, making them suitable for different types of projects. In this guide, we’ll compare these two printing techniques to help you determine which one best fits your business needs.

Printing Method Differences

Sublimation printing is an inkjet process that involves printing a design onto special sublimation paper, which is then heat-transferred onto materials like polyester fabrics, plastics, and metals. The sublimation process transforms solid dyes into gas without passing through a liquid phase, embedding the design into the material’s surface. This method produces vibrant, long-lasting colors, but works best on light-colored polyester fabrics or specially coated surfaces.

DTG printing, on the other hand, directly sprays the ink onto the garment, similar to how a paper printer works. The design is then heat-cured, which bonds the ink to the fabric fibers. DTG is particularly effective for printing on cotton or cotton-blend fabrics and can handle intricate designs with a wide range of colors. Unlike sublimation, DTG can print on dark fabrics by using white ink as a base layer.

Ink and Fabric Compatibility

Sublimation ink is dye-based and becomes part of the fabric, offering vibrant and durable prints on polyester materials. However, it is limited to light-colored fabrics and coated surfaces, as the inks don’t adhere well to cotton or other natural materials. In contrast, DTG uses water-based pigment inks that are absorbed into the fabric fibers, making it suitable for cotton and cotton-blend garments. DTG’s ability to use white ink allows it to produce bright, detailed prints on darker fabrics, which sublimation struggles to achieve.

Process and Equipment Differences

The process for sublimation printing involves first printing the design onto sublimation paper, then using a heat press to transfer the image onto the fabric. This method is straightforward and works well for both full roll fabrics and cut pieces. The equipment varies from small desktop printers to large-format industrial machines, along with heat presses that can range from compact units to large rotary heat machines.

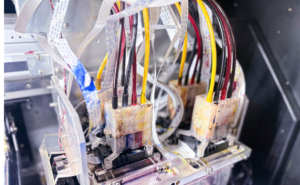

DTG printing starts with a pretreatment step where the fabric is treated to ensure better ink absorption and durability. After the design is printed directly onto the fabric, the garment is heat-pressed or passed through a belt dryer to cure the ink. DTG printers come in various configurations, from single-plate models to more complex setups capable of handling multiple garments simultaneously. Advanced DTG machines can also integrate with screen printing techniques for larger, more versatile production.

Quality, Longevity, and Applications

In terms of print quality and longevity, sublimation offers bright, vibrant colors that are highly durable and resistant to fading, cracking, or peeling. Because the ink becomes part of the fabric, the prints maintain their quality over time, even after multiple washes. However, sublimation is generally limited to polyester fabrics and is less effective on dark colors.

DTG printing produces high-resolution images with excellent detail and color range, especially on cotton garments. However, the prints may fade over time, particularly with frequent washing. Despite this, DTG is highly versatile and can be used on a wide variety of fabrics, including darker materials where sublimation cannot perform as effectively.

Application Differences

Sublimation is ideal for creating all-over designs on polyester fabrics and is also used for printing on rigid products like mugs, bottles, and metal items, though these require special equipment. DTG, however, is primarily used for textiles such as t-shirts, hoodies, and other garments. Due to the size limitations of DTG printers, it is typically used for specific areas of a garment rather than full-coverage printing.

Conclusion

Sublimation and DTG printing each have their strengths depending on the project at hand. Sublimation is perfect for vibrant, long-lasting prints on light-colored polyester and other synthetic materials, while DTG offers flexibility in fabric choices and excels with dark, cotton-based garments. Understanding the differences between these methods can help you choose the best printing technique for your business needs.

-e1723941306789.png)