Direct-to-film (DTF) printing is a cutting-edge technique that transfers intricate designs directly onto PET films, which are then applied to various materials. Whether you’re running a custom printing business or exploring new printing technologies, understanding DTF can offer valuable insights. This guide covers the essentials of DTF printing, its process, and the pros and cons of using this method.

What is DTF Printing?

DTF printing is a digital method that accurately transfers detailed designs onto different fabrics, including cotton, polyester, nylon, and blended materials. The process involves using special DTF inks, films, and hot melt powder to achieve high-definition prints. These prints are applied using heat, ensuring vibrant colors and strong adhesion without the issues of color bleeding or design separation.

The DTF Printing Process

The DTF printing process is straightforward but involves several crucial steps:

- Create Designs: Start by creating digital designs using software like Adobe Photoshop, CorelDraw, or Canva. Save your designs in common formats such as JPG, TIFF, or PDF.

- Print on Film: The design is printed onto a semi-transparent PET film using a DTF printer. The first layer printed is the color layer, followed by a white layer, ensuring that the design stands out on any fabric.

- Apply Powder: Immediately after printing, apply hot melt powder to the wet design. The powder acts as an adhesive, bonding the design to the fabric during the transfer process.

- Cure the Film: Heat the printed film to cure the powder. This step is critical to ensuring that the design adheres well to the fabric. A curing oven or a belt system can be used at around 110°C for a few minutes.

- Cut the Film: Once cured, cut the film to isolate the design, leaving a small margin around the edges for easier handling during transfer.

- Transfer to Garment: Position the film on the garment, design side down, and use a heat press at approximately 160°C for 15-20 seconds. Each fabric type may require slight adjustments in temperature and time.

- Peel Off the Film: After the garment cools, carefully peel off the film. Ensure the design remains fully transferred to the fabric.

- Post-Pressing: For enhanced durability, press the garment once more with heat. This step helps solidify the print, ensuring it can withstand washing and wear.

Essential Equipment for DTF Printing

To get started with DTF printing, you’ll need the following equipment:

- DTF Printer: Choose a model based on your printing needs. Smaller printers handle prints up to 35cm wide, while larger models can manage up to 1.2 meters.

- DTF Hot Melt Powder: This adhesive powder ensures that the design adheres to the fabric. Options include TPU and anti-sublimation powders, each offering different levels of durability and wash resistance.

- DTF Film: A high-quality PET film, around 90μ thick, ensures easy transfer and excellent ink absorption.

- DTF Ink: Available in CMYK+W, as well as fluorescent colors, these inks are crucial for vibrant and accurate prints.

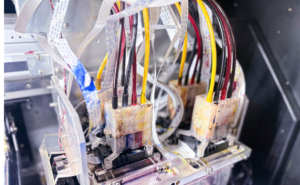

- Powder Shaker: This machine evenly applies the hot melt powder, especially useful for large-scale operations.

- Heat Press Machine: A flatbed heat press is ideal for most fabrics, while a rotary heat press is better for continuous, large-scale printing.

- Design Software: Software like Adobe Illustrator or CADlink is essential for creating detailed, professional-quality designs.

Pros and Cons of DTF Printing

Pros:

- Durable, high-quality prints with vibrant colors.

- Versatile across various materials, from cotton to leather.

- Cost-effective for bulk production without the need for pre-treatment.

- Faster turnaround with a straightforward process.

- Environmentally friendly with less waste generated.

Cons:

- High initial investment for equipment.

- Limited scalability for large-format prints.

- The “handfeel” of the print may not be as soft as with other methods like DTG or sublimation.

What UniPrint Offers

UniPrint provides all the essential tools for successful DTF printing. Our DTF printer models cater to different production scales, from the compact 300 series for smaller projects to the robust 600 series for larger outputs. We also offer high-quality DTF films, powders, and inks to ensure seamless printing. For all your DTF printing needs, UniPrint delivers reliable, quality-assured products to help your business thrive.

-e1723941306789.png)