Personalized products, like custom T-shirts, are in high demand today. For those looking to enter the T-shirt printing business, understanding the various printing methods is crucial. This guide covers the five most common T-shirt printing techniques, explaining how each works and the pros and cons of each method.

Types of T-Shirt Printing Techniques

The five primary T-shirt printing techniques are:

- Direct-to-Garment (DTG) Printing

- Screen Printing

- Dye Sublimation Printing

- Direct to Film (DTF) Printing

- Heat Transfer Vinyl Printing

Each method has its unique process, advantages, and best-use scenarios. Let’s dive into how these techniques work.

How These T-Shirt Printing Techniques Work

1. Direct-to-Garment (DTG) Printing

What is DTG Printing?

DTG printing is a modern method that involves digitally printing designs directly onto fabric. This technique is ideal for highly detailed, full-color designs on cotton garments.

DTG Printing Process:

- Pre-treatment: Apply a pre-treatment solution to the fabric using a spray gun or an automated device.

- Drying: Use a heat press or tunnel dryer to dry the pre-treated fabric.

- Printing: Place the fabric on the printer platen, import the design, and print directly onto the garment.

- Curing: After printing, heat press the garment at 160°C for 30 seconds to cure the design.

2. Screen Printing

What is Screen Printing?

Screen printing uses a mesh screen as a stencil to apply ink to fabric. This method is known for producing vibrant, durable prints and is commonly used for high-volume orders.

Screen Printing Process:

- Screen Preparation: Create a screen with the desired design using a photosensitive emulsion.

- Ink Application: Pour ink onto the screen and use a squeegee to press the ink through the mesh onto the fabric.

- Printing: Adjust the machine settings (pressure, speed, temperature) and begin printing.

- Post-Processing: After printing, dry and cure the fabric to set the design.

3. Dye Sublimation Printing

What is Sublimation Printing?

Dye sublimation involves printing designs onto transfer paper, which is then heat-pressed onto polyester fabrics. The dye turns into a gas, penetrating the fabric and creating vibrant, long-lasting prints.

Sublimation Printing Process:

- Design Creation: Use graphic design software to create the design.

- Printing: Print the design onto sublimation transfer paper.

- Heat Transfer: Place the paper on the fabric and use a heat press at up to 200°C to transfer the design.

- Finishing: Remove the transfer paper to reveal the design and allow the fabric to cool.

4. Direct to Film (DTF) Printing

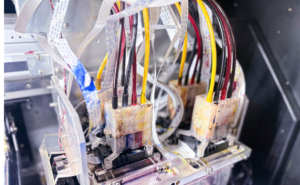

What is DTF Printing?

DTF printing involves printing designs onto a special PET film, which is then transferred onto fabric using heat and pressure. This method is versatile and works on various fabrics.

DTF Printing Process:

- Printing: Print the design onto PET film using a DTF printer with CMYK and white inks.

- Powder Application: Apply hot melt adhesive powder to the wet ink on the film.

- Curing: Heat the film to cure the powder and set the design.

- Transfer: Press the film onto the fabric using a heat press at 160-170°C for 15-20 seconds.

- Peeling: Allow the film to cool before peeling it off to reveal the design.

- Post-Pressing (Optional): Press the garment again to enhance durability.

5. Heat Transfer Vinyl Printing

What is Vinyl Transfer Printing?

Vinyl transfer printing involves cutting designs from vinyl sheets and then heat-pressing them onto fabric. This method is ideal for simple, text-based designs.

Vinyl Transfer Printing Process:

- Design Creation: Create the design and print it onto heat transfer vinyl.

- Cutting: Cut the design using a vinyl cutter.

- Weeding: Remove excess vinyl, leaving only the desired design.

- Heat Pressing: Place the vinyl design on the fabric and heat press it. Peel off the backing after cooling.

Pros and Cons of Each Printing Technique

Each printing technique has its own set of advantages and disadvantages:

| Technique | Pros | Cons |

|---|---|---|

| DTG | High-quality, full-color prints; no minimum order. | Higher cost per print; slower for large volumes. |

| Screen | Cost-effective for bulk; vibrant, durable prints. | Not ideal for complex designs; longer setup time. |

| Sublimation | Excellent for all-over prints on polyester. | Limited to light-colored, polyester fabrics. |

| DTF | Works on various fabrics; vibrant, detailed prints. | Higher cost; complex process. |

| Vinyl | Durable; great for text-based designs. | Limited color options; not ideal for detailed designs. |

Choosing the Best T-Shirt Printing Method

There isn’t a one-size-fits-all answer when it comes to selecting the best T-shirt printing method. It depends on factors like print volume, fabric type, design complexity, and budget:

- DTG is ideal for small batches with detailed designs on cotton.

- Screen Printing is best for high-volume orders with simple, vibrant designs.

- Sublimation is perfect for all-over printing on polyester.

- DTF is versatile and works on various fabrics.

- Vinyl is great for durable, text-based designs.

What Printing Methods Are Available with UniPrint?

At UniPrint, we offer solutions for DTG, Sublimation, and DTF printing methods. For more details on our services or to explore your options, feel free to contact us.

FAQs

What is the Most Suitable Printing Technique for Shirts?

It depends on the fabric, design, and order quantity. For polyester, sublimation is ideal, while DTG or DTF suits cotton.

Which Shirt Printing Method Offers the Highest Durability?

Screen printing and sublimation are generally more durable than DTG.

What Printing Technique is Effective for Small Businesses?

DTG, DTF, and Vinyl are flexible for small orders and custom designs.

What Types of Ink are Used in Common T-Shirt Printing Techniques?

DTG uses water-based pigment ink, DTF uses a special pigment ink, sublimation uses sublimation ink, and screen printing uses plastisol ink.

-e1723941306789.png)