Are you planning to launch a custom socks business and need expert guidance to ensure profitability? You’ve come to the right place.

Starting a successful socks printing business demands careful planning, a deep understanding of the market, and consistent effort. This article will provide comprehensive insights into sock printing and the right socks printer for your business. But first, let’s explore why custom socks are in high demand.

Why Start a Socks Printing Business?

Many entrepreneurs enter the socks printing industry without recognizing its full potential. However, with strategic planning, you can significantly increase your profits.

Custom socks offer a unique opportunity to cater to specific customer demands, allowing you to charge a premium over standard socks. Customization adds value, making these products more appealing to various markets, including fashion, branding, and special events.

The popularity of custom socks has been on the rise for years. They’re trendy, versatile, and even used for promotional purposes. You can create designs tailored to your customers’ preferences, catering to special occasions or specific needs like athletic socks, logo socks, or dress socks.

Over the last decade, there has been a surge in demand for personalized products, and custom socks are no exception. Today’s consumers want products in their preferred designs and colors. For example, face socks, which feature personalized images, are a trending item that combines fun and personalization.

Custom sock printing is a business with low startup costs and high returns. With the latest digital socks printers, you can leverage print-on-demand technology to produce socks as needed, ensuring quick turnaround times and eliminating issues like overproduction.

Why Choose DTG Socks Printing Over Sublimation Printing?

When deciding how to print your custom socks, the choice of printing technology is crucial. The market offers various socks printing machines with different features, capacities, and sizes. However, not all are suitable for your business, so it’s important to choose wisely.

Screen Printing

Screen printing is a widely used method for creating custom socks. It involves transferring ink onto the fabric through a mesh screen, where each color requires a separate screen. While this method allows for printing on dark fabrics, it comes with limitations, such as high initial setup costs and restrictions on the number of colors that can be used.

Sublimation Printing

Sublimation printing is another popular method, especially for polyester socks. It involves printing a design onto sublimation paper and then transferring it to the fabric using heat. While this method produces smooth prints, it’s limited to polyester or high-polyester blends and offers lower quality compared to DTG printing.

DTG Socks Printing

DTG (Direct-to-Garment) printing is the preferred method for high-quality custom socks. This technology uses water-based inkjet printing to apply designs directly onto the fabric, resulting in vibrant colors and intricate details, similar to a photograph. DTG printing has no color limitations and supports small-quantity orders, allowing for high precision regardless of the complexity of the design.

Why Choose DTG Printing?

360-Degree Spiral Printing

DTG printers allow for 360-degree spiral printing, enabling you to print all around the sock, unlike sublimation printing, which requires a flat surface.

No Heat Press Lines

With DTG printing, your socks won’t have the unsightly heat press lines often found in sublimation printing, ensuring a smoother finish.

No White Leakage

DTG printing ensures the ink penetrates deep into the fabric, preventing white leakage when the socks are stretched, a common issue with sublimation printing.

Versatile Material Application

DTG printing works on a wide range of materials, including cotton, polyester, nylon, bamboo, and wool, while sublimation is limited to polyester.

Shape Retention

DTG printing maintains the original shape of the sock, unlike sublimation, which can alter the sock’s shape and texture.

Design Integrity

DTG printing excels in maintaining design integrity, offering seamless 360-degree printing for smoother patterns, unlike the uneven results often seen in sublimation printing.

Advantages of UniPrint Socks Printing Technology

Higher Color Fidelity and Precision

UniPrint’s socks printers use a 4-color ink system (CMYK), with an option for an 8-color system for reactive cotton, ensuring high color fidelity and precision. This technology allows you to achieve perfect color accuracy and balance in your designs.

Low MOQ Orders

Our printers utilize print-on-demand technology, allowing you to keep the Minimum Order Quantity (MOQ) as low as needed. This feature is ideal for small orders, enabling you to print designs as they are ordered, reducing inventory costs and waste.

Versatile Material Options

UniPrint socks printers are compatible with various materials, including cotton, polyester, bamboo, nylon, and wool, offering flexibility in your product range.

Fast Delivery

Our printers are designed for efficiency, with the capability to produce up to 500 pairs of socks per day, allowing you to handle bulk orders with ease.

Choosing the Right Socks Printing Machine for Your Business

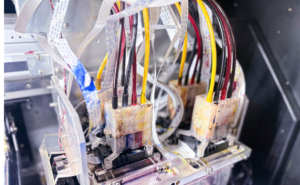

Selecting the right printer is crucial for your socks printing business. The UniPrint Spiral Socks Printer is an excellent investment, offering high-speed, high-resolution printing with advanced spiral technology.

Advantages of the UniPrint Spiral Socks Printer

Different Printing Resolutions

Our printers can adapt to various print heads for different resolutions, ensuring that you get the right quality for your specific needs.

Faster Speed

With a 30% improvement in printing speed compared to older models, our spiral socks printer can produce up to 500 pairs per day, making it ideal for businesses that need to fulfill large orders quickly.

Upgraded Roller Precision

Our printers feature an advanced roller system with high precision control, ensuring consistent quality across all prints.

Why Choose UniPrint?

State-of-the-Art Printing Solutions

UniPrint offers the latest in digital printing technology, from printers and inks to essential equipment like heaters, steamers, dewaterers, dryers, and washers.

On-Time Support

We provide comprehensive customer support through multiple channels, including phone, email, WeChat, and WhatsApp. Our team is ready to assist with installation, operation, and troubleshooting.

Warranty

UniPrint offers a 1-year warranty on printers, excluding the ink system and related spare parts. We also provide lifetime maintenance support for our regular customers.

Timely Delivery

We ensure that your order is delivered within 15 to 30 days, with custom solutions possibly requiring more time. All equipment is securely packed to prevent damage during transit.

Let’s Grow Together

The demand for custom socks is growing, making it a lucrative business opportunity. If you’re ready to start your socks printing business, UniPrint is here to support you with cutting-edge printing solutions. We believe in mutual growth and are committed to helping you achieve your long-term goals.

Contact us today, and let’s embark on this journey together. Our representatives are just a call or message away, ready to assist you with all your needs.

-e1723941306789.png)